涡轮磨粒流抛光技术的原理

涡轮磨粒流抛光技术的原理是利用含有磨粒的半固态介质流动,通过高压推动介质进入工件的内部或表面,使其与工件产生摩擦,从而实现精细的去除加工

磨粒流抛光服务

磨粒流抛光服务

Innovative processes help you polish high quality products. For customers of various processing requirements to provide a high precision quality, high efficiency polishing scheme

Know more about

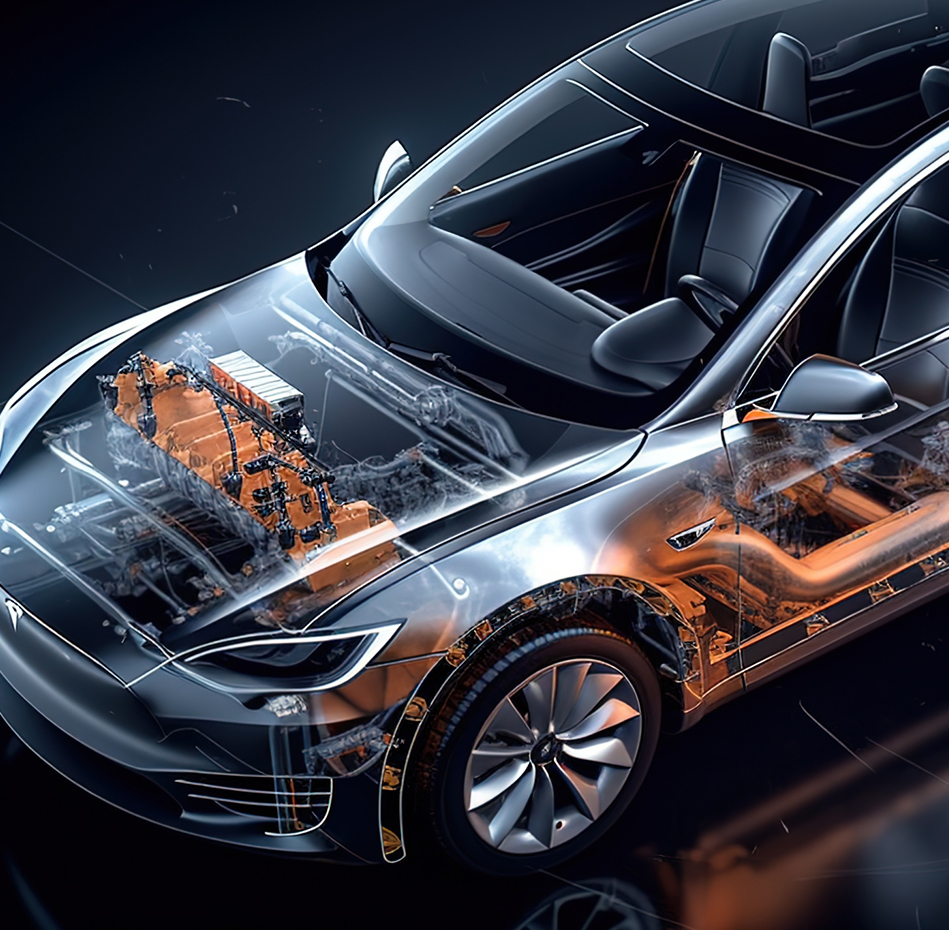

China has the largest automobile market in the world, and the quality of parts determines the performance, reliability and service life of the vehicle. Therefore, the precision of vehicles for parts is getting higher and higher. As an efficient and precise polishing and deburr processing process, grinding particle flow polishing is favored by many manufacturers at home and abroad.

Know more aboutEfficient, ultra-reliable engineering is crucial in the aerospace industry, which is why manufacturers want their components and production processes to meet such stringent requirements. The excellent surface roughness values and the rounded & deburring process play a fundamental role in significantly reducing engine friction.

Know more aboutIn the field of metal additive products, the surfaces of various bending channels, blade impeller, tooth surface and heterosexual cavity have high hardness and poor roughness, while the polishing of 3D printed parts is preferred by particle flow polishing.

Know more aboutThe roughness problem of devices and parts can greatly affect the life and health of patients. Due to the particularity of its application scenarios in the application of medical devices, it should pay the most attention to surface treatment, so as to provide higher reliability, longer life and higher accuracy, and provide solutions to various key problems of medical devices.

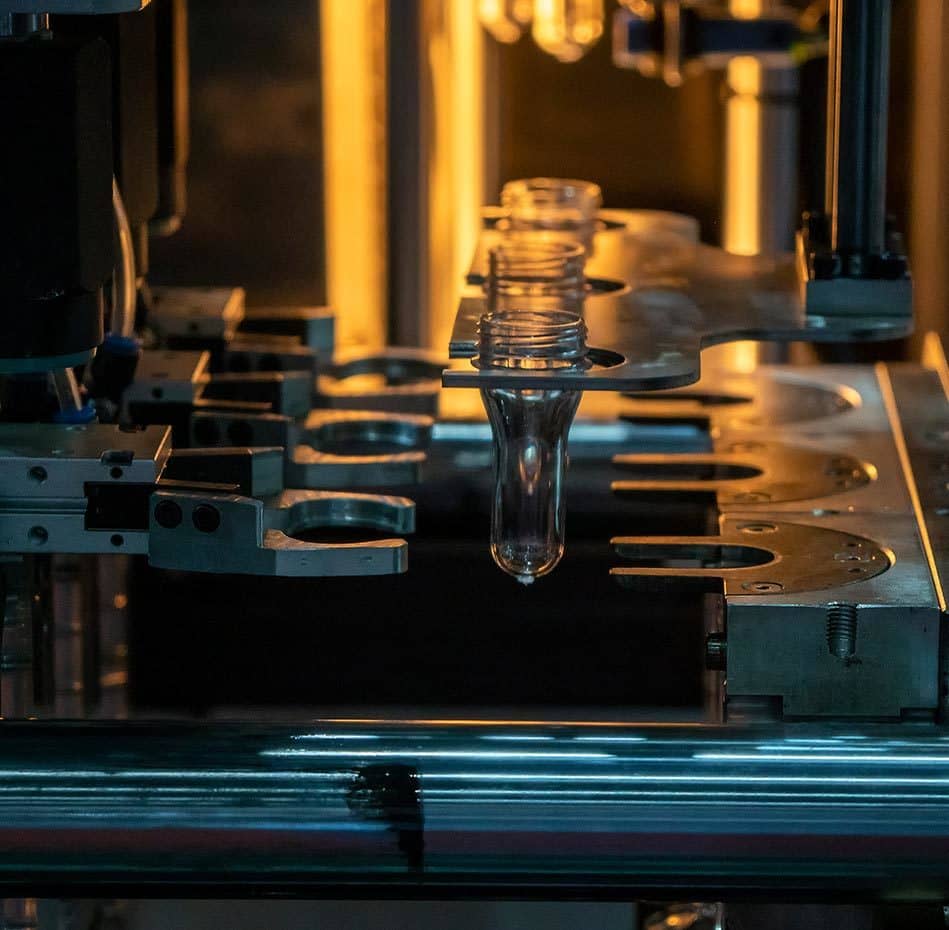

Know more aboutPolishing in the mold making process is an important process, with the increasingly widely application of plastic products, the appearance of plastic products quality requirement is more and more high, so the plastic mold cavity surface polishing quality to improve accordingly, especially the mirror and highlight surface mold surface roughness requirements, so the requirement for polishing to burr is higher.

Know more aboutBecause of the surface characteristics of the turbine blade, the traditional mechanical or manual polishing, the accuracy and parity control stability is insufficient. Because of its use of non-Newtonian fluid abrasive, with good mobility, very evenly in contact with the polishing surface for grinding under pressure. And through the pressure, time, and abrasive granularity, to control the precision. The polished turbine blades have less friction and the blade surface has stronger oxidation resistance, which can significantly improve their performance and service life.

Know more about

Polytech Seiko Technology is mainly engaged in the research and development and manufacturing of special surface treatment equipment and related media and consumables, and is committed to providing environmentally friendly products and innovative surface treatment solutions for domestic and foreign customers.